The butt fusion welding machine is shipped with following vulnerable parts:

- Reducer inserts

- Fast installing screws

- Carbon brushes

- Hydraulic quick coupling

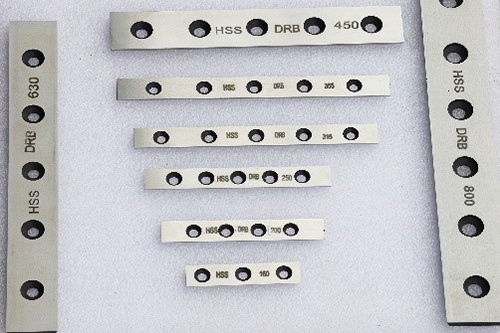

HSS reducer inserts are designed with double cutting edges to deliver stable and durable performance.

WELPING has sufficient stock of replacement parts which can be delivered via ocean, air or express transportation.

Whenever you have any problems about machine operations, installation, daily maintenance or else, please don’t hesitate to contact us via email or phone. Our dedicated technicians will give you full technical support until you solve the problem.

We provide 18 months warranty for all butt fusion machines and extrusion welders. After-sales service is also available for products out of warranty. If there is any problem happening to your fusion equipment, please contact us for help. Our technicians will diagnose the problem according to the photos or videos you offered and then provide an optimal solution.

What is butt fusion? And what are its advantages?

Butt fusion is a thermofusion process and it involves the simultaneous heating of the ends of two pipe/fitting components which are to be joined, until a molten state is attained on each contact surface. The two surfaces are then brought together to form a stable fusion joint.

Butt fusion can form stable and reliable joints with easy operations. It is often used for jointing PE, PP, PVDF, HDPE, MPP pipes.

Can butt fusion be used to joint different types of plastic pipes?

Because different plastic pipes have different heating time and heating temperature, butt fusion is not a good choice for jointing different plastic pipes.

Guide to butt fusion jointing

In order to achieve an acceptable joint, three preparation works are essential:

- Identify the pipe diameter to be processed and select a proper butt fusion equipment.

- Check the wires on site to see whether it is matchable with the machine motor.

- Execute test welding to examine the butt fusion welding performance prior to formal welding.

Applicable pipe materials and welding process for PE/HDPE pipes

Butt fusion is applicable to PE, HDPE, PP, PVDF, MPP pipes.

Butt fusion welding process for PE/HDPE pipes

- Power and test your butt fusion equipment.

- Cut the plastic pipes into desired length.

- Fix the cut pipes into the clamping tool.

- Plane the pipe end and ensure two pipe ends to be jointed can align with each other.

- Clean the pipe end and heat the end until its surface melts using the heating plate.

- Take out the heating plate, bring two molten ends together under controlled pressure for a specific cooling time until a homogeneous fusion joint is formed.

How is the butt fusion joint quality?

butt fusion can create stable and firm fusion joint with excellent pressure resistance performance.

How do I choose the right butt fusion machines for my pipe welding job?

Firstly determine the maximum and minimum size of the pipe to be welded, then select the exact size. For example:

The diameter of the welded pipe is 315mm-630mm, then our WP630A or WP630B can definitely meet the pipe specifications. However, if the size range is 200mm-630mm, then a combination of 2 but fusion machines is required to meet the requirements.

However, if the customer needs a non-standard machine size, such as a machine using inch as a measuring unit, you are welcome to contact our sales representative, we will definitely give suggestions according to your specific needs.

Can I get a butt welding machine with pipe welding range from 63mm to 315mm?

We offer two models of butt fusion welding machines including WP315A and WP315B. The standard pipe welding range is 90-315mm.

Although the clamp with sizes of 63mm and 75mm can be installed to WP315A or WP315B, it’s not recommended to clamp pipes below 90mm on the butt welding machine.

- If the butt fusion welding machine is not often required to weld on plastic pipes with a diameter of 63mm, we recommend you to choose WP315A or WP315B hydraulic butt fusion machine with welding range of 110mm-315mm, and WP160C manual butt fusion machine. This machine combination can cover all the requested requirements along with saving costs.

- If welding plastic pipe with a diameter of 63mm is often involved, standard hydraulic butt fusion machine is highly recommended, including models WP315A, WP315B, WP160A, and WP160B.

Are you a manufacturer or trading company?

We are a company which has been focusing on manufacturing and exporting since 2010, located in Puyang Town, Xiaoshan District, Hangzhou City, Zhejiang Province, China.

What is the lead time of the product?

We usually have our best-selling products in stock. Furthermore, we can finish a 20ft container in 15 days and a 40ft container in 25 days.

Can I use my own brand?

Definitely, we are happy to support your business as well as to produce machines with your own brand along with the selected colors. Please note that there will be a minimum order quantity for using OEM brand and color. Should you be interested, kindly consult to our procurement staff for further details.

Do you provide after-sales service?

Usually, we will provide spare parts when we deliver the machine. Moreover, if you buy a large quantity of products, we will provide you with a list of spare parts given. At the same time, we have some partners around the world, and they can also assist you. Furthermore, we can also provide online support for you.

Do you test all products before delivery?

Yes, we test our products both during the production process and before shipment to ensure the consistency of our products.