WELPING built a new factory spanning an area of 20000 square meters, which has been put into operation since 2022. This ensures high production capacity of butt fusion machines.

Aluminum casting is adopted to process pipe butt fusion equipment, providing lower cost and higher production efficiency, compared with aluminum sand casting.

WELPING is the first one in China to make use of aluminum casting for manufacturing clamp reducers in diameters less than 630mm. This process doubles the efficiency during the production.

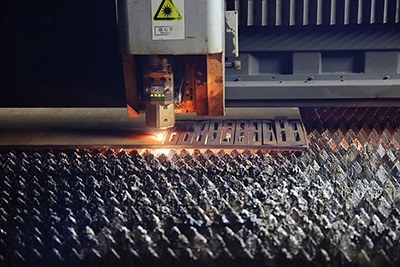

Traditionally, aluminum sand casting is used to process large size butt fusion machines (800mm-1600mm). However, aluminum sand casting has the disadvantages of low strength, surface defects, high production cost, etc. In order to address these problems, WELPING switched to adopt sheet metal laser cutting and welding. 12000W high power laser cutting machine is equipped in this workshop, allowing for high product quality and production efficiency.

Our factory is well equipped with advanced CNC processing equipment. It boasts a series of CNC machine tools and machining centers, enabling us to machine various parts in different sizes.

WELPING built a sheet metal welding workshop for joining metals to meet different customer needs.

WELPING has an experienced, sophisticated and dedicated inspection and assembly team, which ensures finished butt fusion machines always have consistent quality.