Socket Fusion Welder, WP32TB / 63TB

(Plastic Pipe Welding Machine, Socket Fusion Machine)

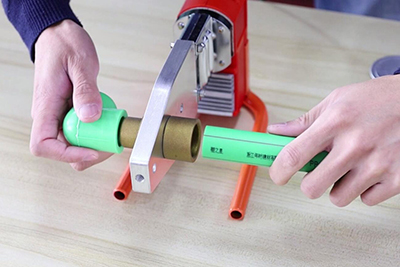

WELPING WP32TB series socket fusion welder is suitable for welding PPR, PB and PE plastic pipes and fittings of O.D. 20mm, 25mm and 32mm. And our WP63TB series socket fusion welder is suitable for welding PPR, PB and PE plastic pipes and fittings of O.D. 20mm, 25mm, 32mm, 40mm, 50mm and 63mm.

Application

Technical Data

- Suitable materials: PE, PP, PB, PVDF

- Welding range: 20-25-32mm

- Power supply: 220/110V 50/60Hz, 1PH

- Total power: 800 W

- Ambient temperature: - 20 - 85ºC

- Relative humidity: 40~95%

- Working temperature: 220ºC-290ºC

- Handle alarm temperature: >310ºC

- Leakage of electric current: <5mA

- Net weight: 3.5 kg

- Packing Size: 39×20.5×8cm

Model: WP32TB

- Suitable materials: PE, PP, PB, PVDF

- Welding range: 20-25-32-40-50-63mm

- Power supply: 220/110V 50/60Hz, 1PH

- Total power: 1.0 KW

- Ambient temperature: - 20 - 85ºC

- Relative humidity: 40~95%

- Working temperature: 220ºC-290ºC

- Handle alarm temperature: >310ºC

- Leakage of electric current: <5mA

- Net weight: 7.8 kg

- Packing Size: 45×25.5×12cm

Model: WP63TB

- Suitable materials: PE, PP, PB, PVDF

- Welding range: 75-90-110mm

- Power supply: 220/110V 50/60Hz, 1PH

- Total power: 1.2 KW

- Ambient temperature: - 20 - 85ºC

- Relative humidity: 40~95%

- Working temperature: 220ºC-290ºC

- Handle alarm temperature: >310ºC

- Leakage of electric current: <5mA

- Net weight: 8.5 kg

- Packing Size: 45×25.5×12.5cm

Model: WP110TB

| Model | WP32TB | WP63TB | WP110TB |

| Suitable materials | PE, PP, PB, PVDF | PE, PP, PB, PVDF | PE, PP, PB, PVDF |

| Welding range | 20-25-32mm | 20-25-32-40-50-63mm | 75-90-110mm |

| Power supply | 220/110V 50/60Hz, 1PH | 220/110V 50/60Hz, 1PH | 220/110V 50/60Hz, 1PH |

| Total power | 800 W | 1.0 KW | 1.2 KW |

| Ambient temperature | - 20 - 85ºC | - 20 - 85ºC | - 20 - 85ºC |

| Relative humidity | 40~95% | 40~95% | 40~95% |

| Working temperature | 220ºC-290ºC | 220ºC-290ºC | 220ºC-290ºC |

| Handle alarm temperature | >310ºC | >310ºC | >310ºC |

| Leakage of electric current | < 5mA | < 5mA | < 5mA |

| Net weight | 3.5 kg | 7.8 kg | 8.5 kg |

| Packing Size | 39×20.5×8cm | 45×25.5×12cm | 45×25.5×12.5cm |

Features

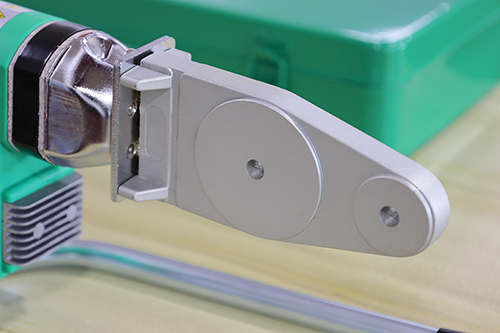

- The industrial-grade mold and thick heating panel ensure appropriate welding temperature;

- The double-layer heat insulation plate effectively prevents heat dissipation;

- Quality aluminum heat radiators have the capability to extend the life of the machine;

-

-

-

Die Head with Superior Thickness

Compared with its counterparts, the die head of the socket welder is much thicker.

Furthermore, the die head is ideally forged with pure aluminum, three layers of high-quality Teflon, and spraying and baking Daikin coating under high temperature, resulting in high temperature resistance.

-

WELPING is a professional manufacturer of fusion machines for jointing HDPE, PP, PVDF, MPP pipes/fittings. We have been focusing on the R&D, manufacturing, and sales of fusion welding equipment since 2005. Products range includes butt fusion machines and extrusion welders.

WELPING has a dedicated team of professional engineers for welding machines R& D and they can give you the most professional advice and technical support for fusion welding equipment. Our factory is equipped with complete manufacturing equipment and hence mass-produced standard products or simply customized products can be delivered within 10-15 days.

Since the very beginning, quality and cost-effectiveness are our benchmarks to develop new products. Adhering to the principle of high quality, we offer a variety of fusion welding machines to meet requirements in different scenarios and from different industries.

WELPING has a dedicated team of professional engineers for welding machines R& D and they can give you the most professional advice and technical support for fusion welding equipment. Our factory is equipped with complete manufacturing equipment and hence mass-produced standard products or simply customized products can be delivered within 10-15 days.

Since the very beginning, quality and cost-effectiveness are our benchmarks to develop new products. Adhering to the principle of high quality, we offer a variety of fusion welding machines to meet requirements in different scenarios and from different industries.

Inquiry

Other Products