As a professional enterprise engaged in machinery and equipment manufacturing, Welping has committed to providing customers with high-quality equipment and professional solutions. As a growing local aquaculture company, Honduras marine aquaculture has been seeking innovative technologies to improve aquaculture efficiency and product quality. Finally, our butt fusion machines for PE pipes were chosen to construct offshore aquaculture farms in Honduras.

In practical application of offshore aquaculture farms, the butt welding machine improved the firmness of the pipeline connection and effectively prevented from seawater erosion and corrosion, which prolongs the service life of the equipment resulting to stronger support for the sustainable development of the marine aquaculture industry.

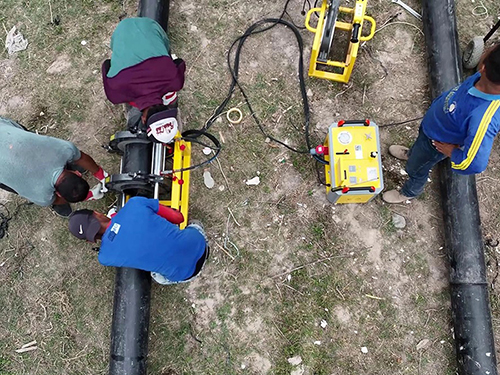

On this project, we adopted butt welding machines for PE pipes, which are specially used for welding plastic materials. Compared with the traditional welding method, the butt welding machine for PE pipes has higher efficiency and better welding quality, which can meet the requirements of plastic pipe welding for offshore farm construction.

By using butt welding machines for PE pipes, Honduras offshore farms successfully accomplished pipeline connections in an easy and quick manner. This efficient welding method improves the welding efficiency and ensures the firmness and tightness of the pipe connection resulting to a reduction of maintenance costs and risks.