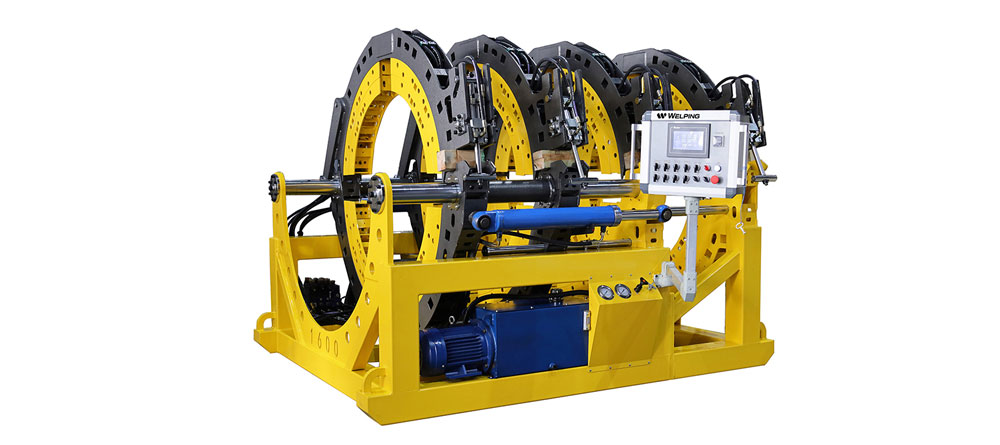

Hydraulic Butt Fusion Machine, WP1600AH

1000-1600mm Plastic Pipe Welding Machine with Manual Locking

The butt fusion machine is ideally used for butt welding of HDPE, PP, PVDF, MPP pipes and fittings.

- Model: WP1600AH

- Welding range: 1000-1600 mm

- Standard reducers: 1200-1400-1600 mm

- Optional reducers: 1000 mm

- Power supply: 380V/50Hz, 3PH

- Total power: 61.5 kW

- Heating plate: 50 kW

- Planing tool: 7.5 kW

- Hydraulic station: 7.5 kW

- Pressure adjusting range: 0-16 MPa

- Max Temperature of heating plate: 270ºC

- Temperature Deviation: ±10ºC

Features

- The machine frame is made by using laser-cut steel plate which has undergone high quality welding. This ensures high stability, high dimensional precision, and beautiful appearance.

- The hydraulic station integrates the hydraulic and electric control systems with an integrated control panel, reducing operation and providing reliable and stable performance.

- The butt fusion machine is equipped with an external hydraulic cylinder that reduces maintenance time. In addition, the cylinder is designed with graphite copper sleeves which provide a smooth contact surface of different parts and reduce the friction force

- The butt welding machine can be optionally equipped with 3 or 4 clamps, making it suitable for fusing solid wall pipes and corrugated pipes.

- Hydraulically-driven locking and opening/closing is optional, which increases the speed of pipe installation by 60%.

- Data logging device is optional

Application

Details

-

-

-

Equipped with a heavy-duty transmission chain and a self-tightening system, the machine has improved transmission efficiency, providing stable performance with reduced noise.

The machine features a high-quality motor made with copper wiring and a thick cutting disc made of smooth and flat aluminum that is not prone to cracking. Additionally, the cutting blade is made of durable high-strength steel, ensuring a long lifespan and reducing the need for frequent replacements.

-

Packaging & Shipping

WELPING is a professional manufacturer of fusion machines for jointing HDPE, PP, PVDF, MPP pipes/fittings. We have been focusing on the R&D, manufacturing, and sales of fusion welding equipment since 2005. Products range includes butt fusion machines and extrusion welders.

WELPING has a dedicated team of professional engineers for welding machines R& D and they can give you the most professional advice and technical support for fusion welding equipment. Our factory is equipped with complete manufacturing equipment and hence mass-produced standard products or simply customized products can be delivered within 10-15 days.

Since the very beginning, quality and cost-effectiveness are our benchmarks to develop new products. Adhering to the principle of high quality, we offer a variety of fusion welding machines to meet requirements in different scenarios and from different industries.

WELPING has a dedicated team of professional engineers for welding machines R& D and they can give you the most professional advice and technical support for fusion welding equipment. Our factory is equipped with complete manufacturing equipment and hence mass-produced standard products or simply customized products can be delivered within 10-15 days.

Since the very beginning, quality and cost-effectiveness are our benchmarks to develop new products. Adhering to the principle of high quality, we offer a variety of fusion welding machines to meet requirements in different scenarios and from different industries.

Inquiry

Other Products